Have you ever wondered about the hidden dangers lurking beneath the depths of our oceans and lakes and how advanced technology is combating them? What challenges do engineers and researchers face in developing effective underwater natural gas leak detection solutions, and how are they overcoming these obstacles?

The increasing global demand for oil and gas, driven by the expanding energy requirements of growing economies, has created a pressing need for affordable energy sources. According to the Medium Gas Term Report 2023, the growth in liquefied natural gas (LNG) capacity is anticipated to increase by 25% from 2022 to 2026. This expansion is primarily a reaction to the rising need for natural gas, both within domestic borders and in international markets.

Simultaneously, a growing environmental consciousness is leading to legislative actions that hold oil and gas companies responsible for minimizing their operations’ environmental risks and impacts. Thus, their focus must be on establishing effective and reliable monitoring systems to address the potential harm caused by leaks and spills of harmful substances. Detecting and pinpointing any leakage of oil, gas, or other contaminants into the surrounding water and ecosystem is crucial to ensure a sustainable and environmentally sound planet.

The significance of underwater gas leak detection

When there are gas leaks, like from pipes or equipment, they release a gas called methane into the air. This gas is not good for the environment because it can make our planet warmer, which we call global warming.

Thus, an early leak detection pipeline is a critical aspect of ensuring safety and environmental protection in the oil and gas industry. In terms of the environment, gas leaks can lead to contamination of aquatic ecosystems, affecting marine life and habitats. This not only results in long-term ecological damage but also poses a significant financial burden for environmental cleanup efforts. Moreover, gas leaks in underwater pipelines can compromise the structural integrity of these systems, potentially leading to costly repairs and production interruptions.

Challenges in developing underwater gas leak detection solutions

Undertaking the detection of gas leaks in underwater environments is a complex and multifaceted endeavor, fraught with many challenges. Compliance with legal regulations, the intricacies of understanding the polymorphic nature of gases underwater, and the requirement for highly advanced equipment are just the beginning. Let’s explore the comprehensive challenges associated with underwater gas leak detection:

Legal requirements

Legal requirements for underwater gas leak detection typically include obtaining permits for underwater activities, conducting environmental impact assessments, adhering to safety standards, and having emergency response plans in place. Companies must also monitor and report gas leak incidents, comply with specific regulations, and ensure continuous compliance with evolving legal standards in their operating areas to avoid legal and environmental consequences.

Polymorphic subject

The challenge of a “polymorphic subject” in underwater gas leak detection refers to the complex and variable behavior of gases in underwater environments. It means that gases in these settings can assume different forms and exhibit diverse behaviors, such as dissolving into water, forming bubbles, or spreading in unpredictable ways.

This complexity and variability make it challenging to accurately detect and identify gas leaks because the behavior of gases can vary based on factors like water temperature, pressure, and the type of gas involved. Therefore, detecting and characterizing gas leaks underwater requires advanced and adaptable detection methods to account for this diversity and complexity.

Special equipment

The challenge related to underwater gas leak detection equipment involves the necessity for costly, high-tech equipment designed to operate effectively in challenging underwater conditions. Acquiring, maintaining, and operating this specialized equipment adds complexity and expense to the detection process. It also requires well-trained personnel to handle and maintain the equipment.

Human resources

This challenge involves the need for people with specialized knowledge and expertise in operating advanced detection equipment, interpreting complex data, and efficiently responding to potential gas leaks in the demanding underwater environment. The success of gas leak detection efforts hinges not only on the sophistication of the equipment but also on the competence of the personnel involved.

Material stress

Material stress in underwater gas leak detection refers to the wear and tear on equipment and materials due to harsh underwater conditions. This includes corrosion from saltwater, pressure at great depths, mechanical wear, fouling by marine organisms, and chemical exposure. The challenge is to ensure that equipment remains reliable and operational despite these factors, as equipment failures can lead to undetected gas leaks, environmental damage, and safety risks.

Expenses

There is no need to mention that implementing underwater gas leak detection solutions is a costly endeavor.

Time-consuming

Finding and identifying gas leaks in underwater environments takes significant time and effort because these areas are vast, often deep, and challenging to access. Detecting gas leaks involves tasks like inspecting equipment, monitoring underwater infrastructure, and analyzing data, which all require thoroughness and can be quite slow due to the complexities of working in underwater conditions.

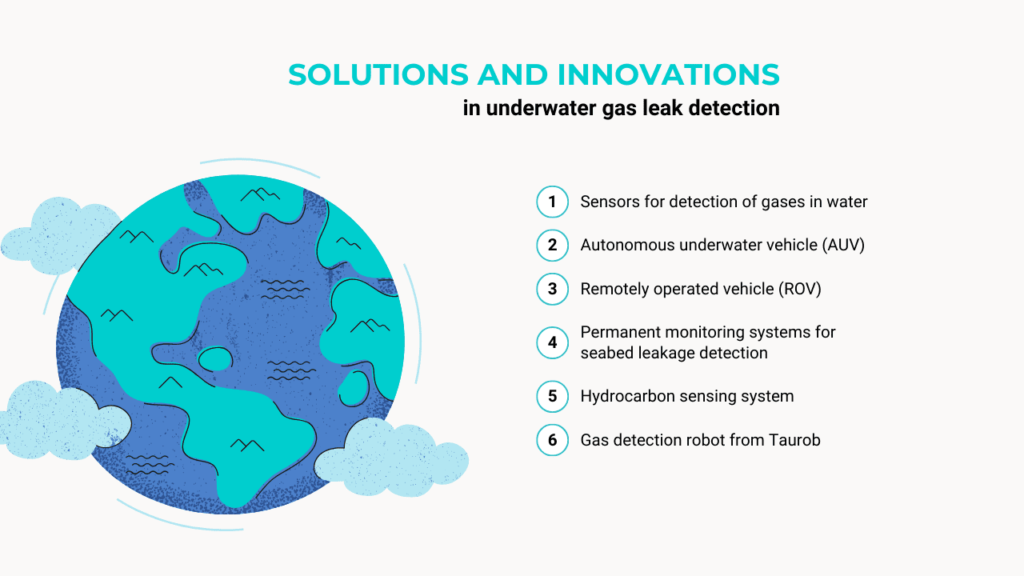

Solutions and innovations in underwater gas leak detection

Underwater gas leak detection solutions often come with a higher degree of complexity and cost than in different scenarios. The intricate nature of underwater environments, characterized by high pressures, variable temperatures, and corrosive elements, requires the use of specialized materials and advanced technologies such as deploying autonomous underwater vehicles (AUVs), remotely operated vehicles (ROVs), and establishing reliable communication networks underwater. Let’s briefly look at solutions and innovations in underwater gas leak detection:

Sensors for detection of gases in water

These sensors use various technologies like electrochemical sensors, optical sensors, or acoustic sensors to monitor the water for the presence of gases like methane or other hydrocarbons. However, it is important to understand that one technology isn’t enough to detect all kinds of leaks everywhere. Thus, you might need to use two or more different sensors together. Such sensors are often part of a broader underwater monitoring and detection system that helps prevent gas leaks from causing environmental damage and operational disruptions.

Sensors are an excellent solution in underwater gas leak detection for several reasons. They enable data aggregation from various technologies, reducing uncertainty and the risk of false alarms. Substance identification is crucial, and gas sensors excel in this regard. Gas sensors not only detect gases but can also be used for identifying oil, as crude live oil often contains dissolved gas. Gas plumes also disperse rapidly in water, serving as early indicators of leaks.

Autonomous underwater vehicle (AUV)

An Autonomous Underwater Vehicle (AUV) is an advanced technology for comprehensive underwater exploration and monitoring. It is equipped with advanced sensors like multibeam echo sounders, traditional side scan sonars, synthetic aperture sonars, and even a photosystem capable of capturing direct documentation of gas bubbles.

It also has methane sniffers and various environmental sensors to measure parameters like temperature, salinity, and turbidity. AUVs offer numerous benefits, including the ability to gather high-resolution data from the ocean floor, investigate underwater ecosystems, and detect environmental factors such as gas leaks.

Remotely operated vehicle (ROV)

Remotely Operated Vehicles (ROVs) are equipped with high-definition cameras, lighting systems, and sensor integration. They provide high-resolution imaging and gather additional data during inspections, making them ideal for pipeline assessments, subsea structure examinations, environmental impact evaluations, and emergency response. Their manipulator arms allow for remote object manipulation, and the capability to collect samples further helps assess ecological impacts.

Permanent monitoring systems for seabed leakage detection

Permanent monitoring systems for seabed leakage detection can include various sensors and instruments, which may encompass sonar, sniffers, and current meters, as well as other types of sensors. These sensors are strategically deployed to continuously monitor the seabed and surrounding areas for any signs of leakage or environmental changes.

For example, sonar systems, gas sniffers, or current meters. The specific combination of sensors used in a permanent monitoring system can vary based on the requirements of the monitoring project and the substances being monitored.

Hydrocarbon sensing system

The Hydrocarbon Sensing System (HSS) by Benthic is a technology designed to detect hydrocarbons in drill returns as they pass through a system known as PROD before being released on the seafloor. The system uses 2 hydrocarbon leak detection sensors placed along the path of drill returns: seawater, drilling cuttings, and any gas or dissolved hydrocarbons from sediment particles. The system estimates the in situ hydrocarbon composition of the material being drilled by analyzing various parameters like tool geometry, drill fluid flow rate, and borehole progression rate.

It can also estimate the rate at which gas infiltrates the borehole. This system serves as an early warning for shallow gas hazards, identifies methane hydrate concentrations, and provides real-time data about gas origin, concentration, and depth, which can be displayed on monitoring equipment onboard a survey vessel. The collected data is stored digitally and can be integrated with other relevant data for analysis and decision-making.

Gas detection robot from Taurob

The Gasfinder, the world’s first specialized gas detection robot, is designed to excel in challenging industrial environments, such as explosive atmospheres, adverse marine weather conditions, and rugged landscapes. With its PL-D-certified safety controller, it complies with ATEX and IP67 standards, making it ideal for a range of gas detection tasks.

These tasks include routine inspections, detecting leaks, collecting data, screening locations, signaling anomalies, providing emergency support, and identifying methane leaks. Besides, the FLIR G300, an optical gas imaging (OGI) camera, is employed to visualize gases and monitor remote or hazardous installations for potential leaks of hydrocarbons or volatile organic compounds.

The combination of these advanced technologies ensures comprehensive gas leak detection capabilities, with the Dräger X-am 8000 as a standout gas sniffer, capable of detecting and analyzing even the smallest leaks of various toxic or flammable gases.

Future trends and prospects

The future of technological advancements in infrastructure inspection holds promising trends and prospects. According to a report by Alan S. Brown, a senior editor at Mechanical Engineering magazine, robots are gradually taking over the role of human technicians in this critical field. This transition is particularly evident in industries like oil, gas, and petrochemicals, which, despite their reluctance to embrace new technology due to the high value of their assets, are increasingly recognizing the benefits of automation.

The rise of Autonomous Underwater Vehicles (AUVs) and Remotely Operated Vehicles (ROVs) only confirms rapid development in this sphere. These advanced robotic systems are equipped with advanced sensors and artificial intelligence, enabling them to inspect and maintain infrastructure with precision and reliability efficiently.

With the ongoing evolution of these technologies, the future holds the promise of safer, more cost-effective, and environmentally friendly infrastructure inspections, transforming the way we ensure the integrity and functionality of critical facilities.